WELCOME

PT SUCOFINDO look forward to a fruitful discussion and a long-lasting partnership

EQUIPMENT SAMPLE PREPARATION IN PT SUCOFINDO UP KELANIS

Hammer Crusher

A Hammer Crusher is a type of crushing machine that utilizes a series of hammers (either fixed or swinging) attached to a rotating shaft to impact and shatter material. When material is fed into the crushing chamber, these rapidly rotating hammers strike it repeatedly, propelling it against breaker plates or screens. This process causes the material to break down into smaller particles. The final product’s fineness is controlled by the size of the screen openings at the bottom of the machine.

- Function: Primarily used for reducing the size of soft to medium-hard, brittle materials. The main size reduction mechanism is impact, often combined with attrition (material rubbing against itself or the machine walls).

- Typical Applications:

- Mining industry (for coal, limestone, etc.)

- Capacity: From a few hundred grams per hour up to tens of kilograms per hour.

- Typical Use: Sample preparation for analysis, material research, or small-scale testing.

Laboratory Scale:

- Rotor Diameter: Typically ranges from 50 mm to 300 mm.

- Motor Power: Usually between 0.1 kW and 3 kW.

- Screen Sizes: Replaceable screens are available with openings from 0.2 mm to 10 mm (or larger), allowing for control over product fineness.

Rotary Sample Divider

A Rotary Sample Divider, also known as a rotary splitter, is used to accurately divide a bulk sample into several smaller, representative sub-samples. This is crucial for ensuring the reliability of subsequent analyses.

- Particle Size Range: Can handle materials from fine powders up to particles (granules) of several millimeters (e.g., 0.1 mm to 30 mm).

- Function: The main material is fed into a hopper and then distributed evenly into multiple collection containers arranged in a rotating manner. This method minimizes segregation errors, leading to highly representative sub-samples.

- Typical Measurements/Capacity: These devices can vary in size based on the volume of the original sample.

- Feed Hopper Volume: From a few liters (e.g., 2-5 liters) for laboratory models up to 20 liters or more for larger samples.

- Number of Dividing Channels/Containers: Typically 6, 8, 10, or 12 sub-sample collection containers.

Raymond Mill

A Raymond Mill, also known as a Raymond Roller Mill, is a type of vertical grinding mill used for grinding non-flammable, non-explosive materials with a Mohs hardness below 7 and moisture content below 6%.

Capacity: From a few tons per hour to hundreds of tons per hour, depending on the model and material.

Function: It grinds materials using rollers that press against a grinding ring, often aided by an air classifier for particle size control. It’s commonly used for minerals like limestone, gypsum, barite, and talc.

Typical Measurements/Capacity:

Roller Diameter: Industrial Raymond mills can have roller diameters from 500 mm to over 1500 mm.

Output Fineness: Typically produces powders with fineness ranging from 80 mesh to 325 mesh (177 µm to 44 µm), with some models capable of finer grinding.

Analytical balance

Analytical balance/scale, is a precision instrument used to measure the mass of an object. They are crucial for accurate quantitative analysis.

- Function: Provides highly accurate weight measurements, essential for preparing solutions, weighing samples for analysis, and quality control.

- Typical Measurements/Capacity:

- Analytical Balances: Offer very high precision.

- Capacity: Typically 120 g to 320 g.

- Readability/Precision: 0.0001 g (0.1 mg) or even 0.00001 g (0.01 mg).

- Precision Balances: Offer slightly lower precision than analytical balances but higher capacity.

- Capacity: From 200 g to several kilograms (e.g., 5 kg, 10 kg).

- Readability/Precision: 0.001 g to 0.1 g.

- Industrial Scales: For much larger quantities, with capacities ranging from kilograms to tons, and lower precision.

- Analytical Balances: Offer very high precision.

Oven

oven is an enclosed chamber used for heating, baking, drying, or curing materials. In laboratory and industrial settings, they are primarily used for drying samples to remove moisture.

- Shelf Capacity: Varies with size, typically accommodating multiple shelves for different samples.

- Function: Provides controlled heating to evaporate moisture from samples, prepare samples for analysis, or conduct heat treatments.

Typical Measurements/Capacity:

- Internal Volume: Laboratory ovens range from small benchtop models of 20 liters to 100 liters. Larger industrial ovens can have volumes of several hundred or even thousands of liters.

- Temperature Range: Most laboratory drying ovens operate from ambient temperature up to 200°C to 300°C, with some specialized ovens reaching much higher temperatures.

Sizing

Sizing, also known as particle size analysis or sieving, is the process of separating particles of different sizes from a mixture.

Measurement Range: From nanometers to millimeters.

Function: It determines the particle size distribution of a material, which is critical for understanding its properties and performance in various applications. The most common method involves using a series of sieves with progressively smaller mesh openings.

Typical Measurements/Equipment:

Sieve Diameter: Common laboratory sieves are 8 inches (200 mm) or 12 inches (300 mm) in diameter.

Sieve Mesh Sizes: Available in a wide range, from very coarse (e.g., 50 mm) down to very fine (e.g., 20 µm), adhering to standards like ASTM or ISO.

Particle Size Analyzers: More advanced instruments use techniques like laser diffraction, dynamic light scattering, or image analysis to measure particle size, offering higher resolution and handling a wider range of sizes than sieving.

Hardgrove Grindability Index (HGI)

Hardgrove Grindability Index (HGI) is a measure of the grindability of coal. It indicates how easily coal can be pulverized in a grinding mill.

Index Range: HGI values generally range from around 30 (very hard to grind) to over 100 (very easy to grind).

Function: A higher HGI value means the coal is softer and easier to grind, requiring less energy in the milling process. This is vital for power plants and other industries that use pulverized coal.

Typical Measurements/Equipment:

Hardgrove Grindability Machine: This specialized machine grinds a standardized coal sample under controlled conditions.

Sample Size: Typically, a 50-gram coal sample (sized between 16 and 30 mesh) is used.

Output: The machine measures the amount of material passing a 200-mesh sieve after a specific number of grinding revolutions (usually 60 revolutions). The HGI is then determined using a calibration curve.

Abrasive Index

Abrasive Index is a measure of a material’s abrasiveness, indicating its tendency to wear down surfaces it comes into contact with, such as grinding mill components or transport systems. It’s particularly important in industries dealing with materials like coal, minerals, and aggregates, as high abrasiveness can lead to significant wear and tear on machinery, increasing maintenance costs and downtime.

- Function: The Abrasive Index quantifies the abrasiveness of a material. A higher Abrasive Index value means the material is more abrasive and will cause greater wear on equipment. This information is crucial for selecting appropriate materials for machinery components (e.g., liners, grinding media) and for predicting wear rates.

- Equipment: The Yancey-Geer-Price (YGP) Abrasiveness Tester (also known as the Hardgrove Abrasive Index Machine) is commonly used to determine the Abrasive Index, especially for coal. While often associated with coal, similar principles apply to testing other abrasive materials.

- Application: Essential for power generation plants (to predict wear on pulverizers and transport systems), mining operations, and material handling facilities.

- How it Works: The YGP tester operates on a principle similar to the Hardgrove Grindability Machine but specifically measures the wear on a standardized test piece (e.g., a steel pin) as the material is ground or agitated. A sample of the material (e.g., coal, usually a specific size range like 4 mesh x 0) is prepared and placed in a grinding chamber along with a set of steel balls and the test piece. The machine then runs for a specified number of revolutions, and the weight loss of the test piece is measured.

Typical Measurements/Output:

- Sample Size: A standardized coal sample is typically used, often around 100 grams (sized between 4 mesh and 0).

- Test Duration: The test runs for a set number of revolutions, usually 200 revolutions.

- Measurement: The primary measurement is the weight loss of a standard steel pin (in milligrams) after the test.

- Index Calculation: The Abrasive Index is calculated based on this weight loss, often with a multiplying factor. The index itself is a dimensionless number.

- Range: Abrasive Index values can vary widely depending on the material, but for coal, they might typically range from 10 to 200 mg (weight loss), translating into varying AI values.

EQUIPMENT COAL LABORATORY IN PT SUCOFINDO UP KELANIS

TM DIRECT

The TM Direct method is a specific procedure used to determine the total moisture content in coal. It’s not a single piece of equipment but rather a methodology that often involves a combination of weighing and drying steps.

- Function: This method directly measures the total amount of water present in a coal sample, including both surface moisture and inherent moisture. It’s crucial for understanding the true mass of coal, its handling characteristics, and its caloric value on an “as received” or “dry” basis.

- Typical Equipment Used: A drying oven (like the MFS Oven or similar), and a precision or analytical balance to weigh the sample before and after drying.

- Process Overview: A coal sample is weighed, then dried in an oven at a specific temperature (e.g., 107 ± 3°C) until a constant weight is achieved. The weight loss corresponds to the total moisture.

FOOM HOOD

The Fume Hood, often referred to as a “Ruang Asam” in Indonesian, is a vital safety device in any chemical laboratory.

- Function: It’s an enclosed workstation with a powerful ventilation system designed to protect laboratory personnel from exposure to hazardous fumes, vapors, dust, and aerosols. It draws air from the lab environment, captures airborne contaminants generated within the hood, and exhausts them safely outside the building or through a filtration system. This is crucial when handling acids, volatile organic compounds, or during reactions that produce toxic gases.

- Typical Features: A sash (movable glass barrier), an exhaust fan, baffles for airflow control, and often utility connections for water, gas, and electricity.

- Safety Importance: Essential for preventing inhalation of dangerous substances and reducing the risk of explosions or fires.

PURIFICATION WATER SYSTEM

A Purification Water System is used to produce high-purity water for various laboratory applications.

Importance: Ensures accuracy and reliability of all wet chemistry analyses.

Function: Laboratory tests require water free from impurities (ions, organic compounds, microorganisms, particles) that could interfere with analytical results. This system uses techniques like deionization, reverse osmosis, distillation, or a combination of these to remove contaminants from tap water, producing deionized (DI) or distilled water suitable for preparing reagents, rinsing glassware, and diluting samples.

Types of Purity: Different grades of purified water (e.g., Type I, Type II, Type III) are produced based on the specific analytical needs, with Type I being the highest purity.

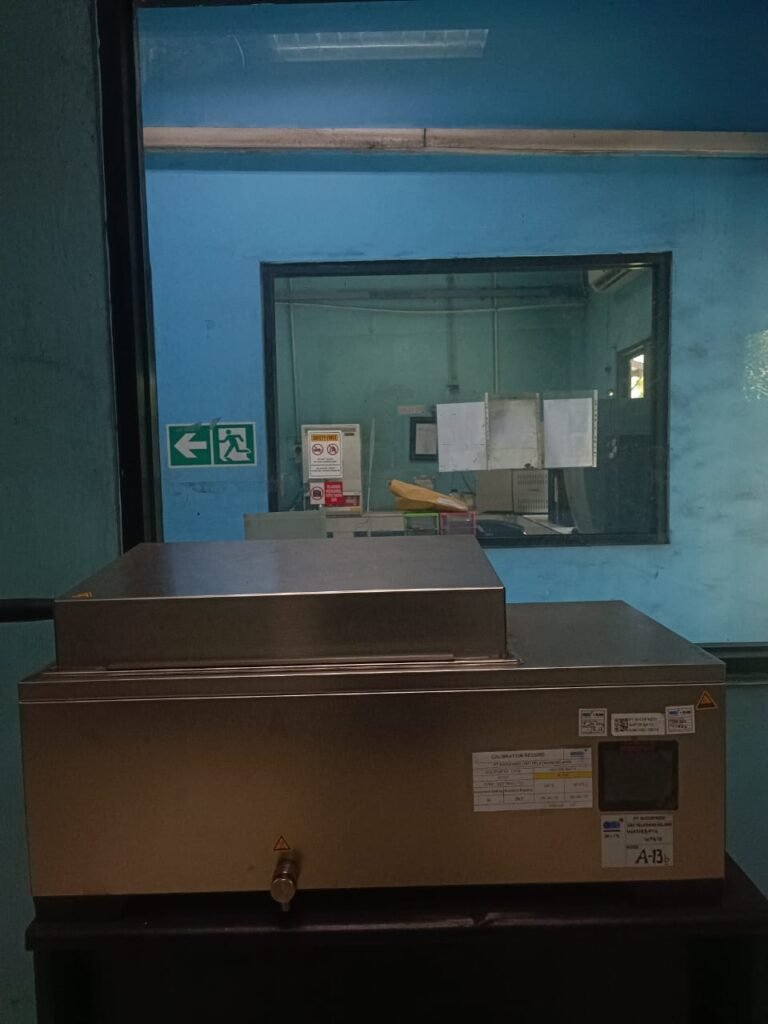

BOMB CALORIMETER

The Bomb Calorimeter is a fundamental instrument for determining the energy content of coal.

- Function: It measures the gross calorific value (GCV) or heat of combustion of a coal sample. The sample is combusted completely in a sealed vessel (the “bomb”) filled with oxygen under high pressure. The heat released from combustion is absorbed by a surrounding water jacket, and the temperature increase of the water is precisely measured. This temperature change is then converted into the calorific value.

- Typical Measurement: Results are expressed in Joules per gram (J/g) or Calories per gram (cal/g), or commonly in kilocalories per kilogram (kcal/kg) or British thermal units per pound (BTU/lb).

- Importance: Crucial for commercial transactions of coal, evaluating energy efficiency, and quality control.

SPECTROPHOMETER

A Spectrophotometer is an analytical instrument used to measure the absorbance or transmittance of light by a sample at different wavelengths.

- Function: It works by passing a beam of light through a sample and measuring how much light is absorbed or transmitted. Different substances absorb light at specific wavelengths, allowing for qualitative identification and quantitative determination of various components in a solution. In coal analysis, it can be used for measuring the concentration of certain elements after they have been brought into solution.

- Principle: Based on Beer-Lambert Law, which states that the absorbance of a solution is directly proportional to the concentration of the absorbing species and the path length of the light.

- Application Example: Measuring the concentration of phosphate, silica, or other elements in water samples or coal leachates.

ANALYTICAL BALANCE

An Analytical Balance is a highly sensitive weighing instrument used for precise mass measurements in the laboratory.

Importance: Essential for almost all quantitative analytical procedures, including moisture determination, ash content, and preparation of samples for elemental analysis.

Function: It measures the mass of a sample to a very high degree of accuracy and precision, typically up to four decimal places (0.0001 g) . This extreme precision is critical for preparing standard solutions, weighing out small quantities of reagents, and performing quantitative analyses where even tiny variations in mass can significantly impact results.

Typical Measurement Range: Capacities usually range from 120 g to 200 g.

MFS OVEN

The MFS Oven is a specialized laboratory oven, often designed for specific coal analysis methods, particularly those requiring precise temperature control for proximate analysis. While not a universally recognized acronym, in the context of coal labs, it likely refers to an oven used for Moisture

- Function:

- Moisture Determination: Used to dry coal samples at a specified temperature (e.g., 107 ± 3°C) to remove moisture content.

- Volatile Matter Determination: Some ovens can reach higher temperatures (e.g., 900°C) with controlled oxygen exclusion, necessary for determining volatile matter in coal.

- Fixed Carbon Calculation: Fixed carbon is determined by calculation from moisture, volatile matter, and ash content.

- Typical Features: High-precision temperature control, often with programmable cycles, and sometimes inert atmosphere capabilities for volatile matter.

- Importance: Fundamental for proximate analysis of coal, which includes moisture, ash, volatile matter, and fixed carbon.

INDUCTIVELY COUPLED PLASMA

Inductively Coupled Plasma (ICP) is a powerful analytical technique used for the elemental analysis of a wide range of samples. It typically comes in two main forms: ICP-Optical Emission Spectrometry (ICP-OES) or ICP-Mass Spectrometry (ICP-MS).

Importance: Provides comprehensive multi-element analysis with high sensitivity and accuracy.

Function: Both techniques use an argon plasma (generated by radiofrequency energy) to atomize and ionize elements in a liquid sample.

ICP-OES: Measures the light emitted by excited atoms and ions in the plasma at specific wavelengths, which are characteristic of each element. The intensity of the emitted light is proportional to the concentration of the element.

Application in Coal: Used to determine the concentration of various trace elements and major elements (e.g., Al, Si, Fe, Ca, Mg, Na, K, Hg, As, Pb, Cd) in coal ash or coal digestates. This is crucial for environmental compliance, understanding ash characteristics, and assessing the quality of coal.

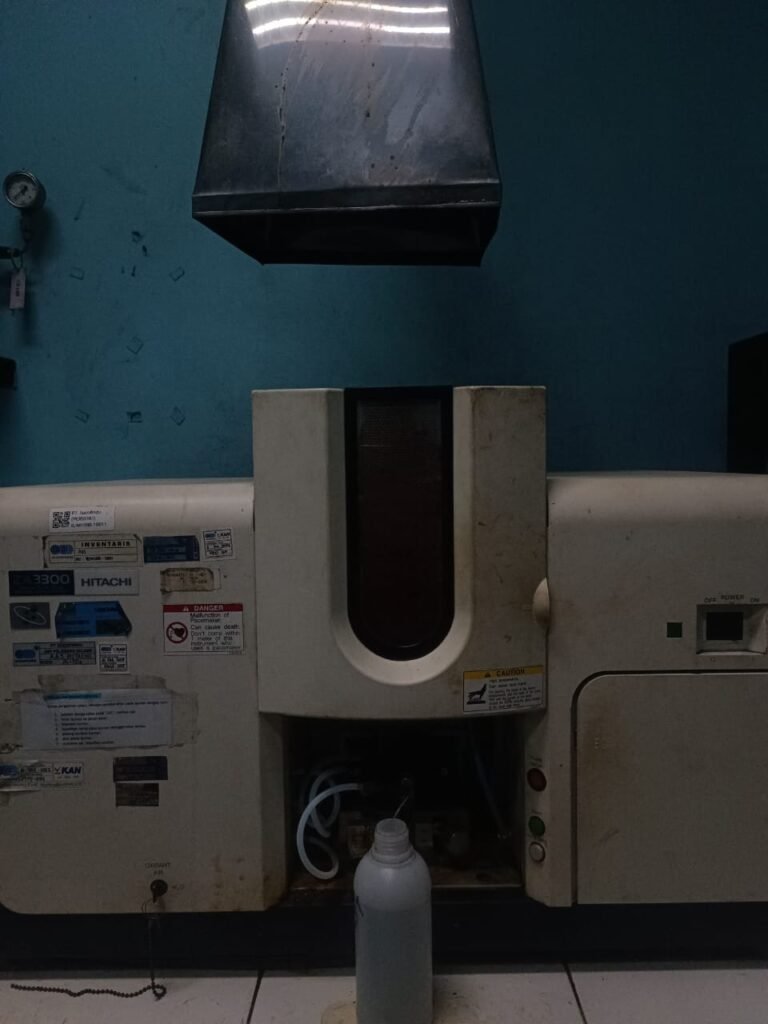

Atomic Absorption Spectrophotometer

An Atomic Absorption Spectrophotometer (AAS) is an analytical instrument used to determine the concentration of specific metallic elements in a sample.

- Function: It works by atomizing a liquid sample (e.g., using a flame or graphite furnace) and then passing light of a specific wavelength (characteristic of the element being analyzed) through the atomic vapor. The atoms in the vapor absorb some of this light. The amount of light absorbed is directly proportional to the concentration of that element in the sample.

- Application in Coal: Used for the precise determination of individual trace metals (e.g., mercury, arsenic, lead, cadmium, chromium) and some major elements (e.g., calcium, magnesium, iron) in coal ash or coal digestates.

- Comparison with ICP: While ICP can analyze multiple elements simultaneously with higher sensitivity, AAS is often more cost-effective for single-element analysis or for elements where it provides sufficient sensitivity.

- Importance: Essential for environmental monitoring and regulatory compliance regarding heavy metal content in coal and its combustion by-products.

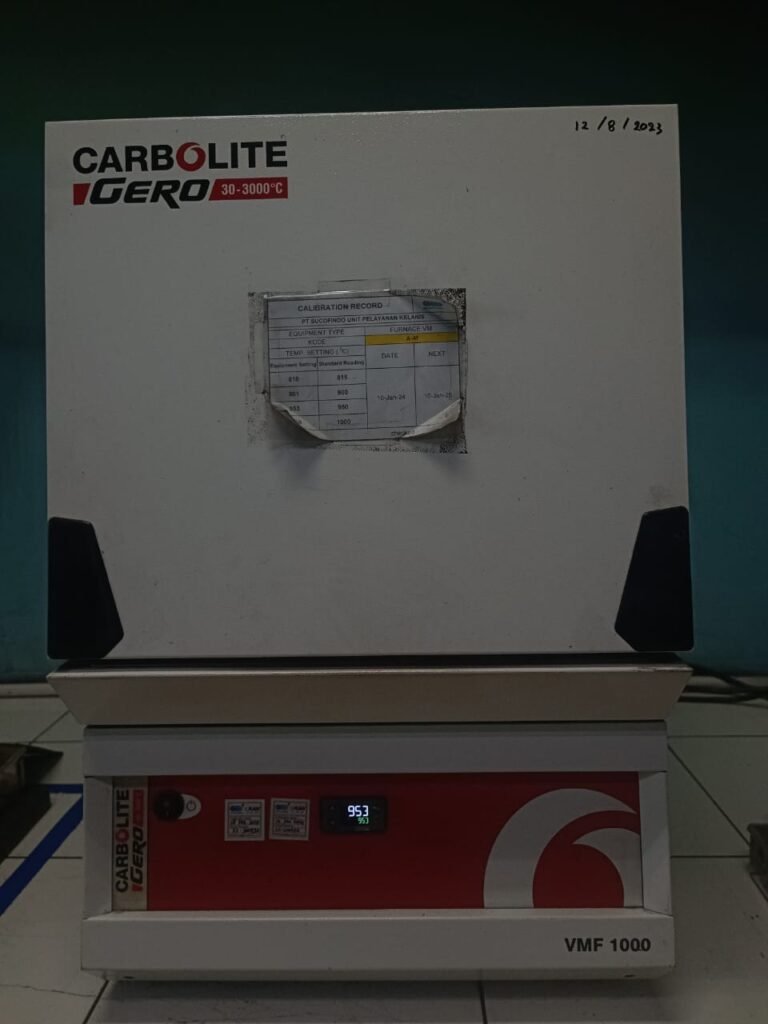

FURNACE

A Furnace in a coal lab context specifically refers to high-temperature ovens used for determining ash content and volatile matter (VMF – Volatile Matter Furnace).

- Ash Furnace:

- Function: Used to determine the ash content of coal. A coal sample is completely combusted in air at a high temperature (e.g., 750°C – 850°C) until all combustible material is removed, leaving behind only the inorganic residue (ash).

- Typical Temperature: Usually between 750°C and 850°C, depending on the standard.

- Importance: Ash content is a key parameter for coal quality, influencing its market value, handling properties, and potential for slagging/fouling in boilers.

- Volatile Matter Furnace (VMF):

- Function: Used to determine the volatile matter content of coal. A coal sample is heated rapidly to a high temperature (e.g., 900°C – 950°C) in an inert atmosphere (or limited air access to prevent combustion) for a specific duration. The weight loss under these conditions, after accounting for moisture, represents the volatile matter.

- Typical Temperature: Usually 900°C to 950°C.

- Importance: Volatile matter affects the ignition characteristics, flame stability, and combustion behavior of coal.

Ash Fusion Temperature

An Ash Fusion Temperature (AFT) Tester is specialized equipment used to determine the characteristic temperatures at which coal ash deforms and melts.

- Function: A cone-shaped pellet of coal ash is heated in a precisely controlled furnace (often with controlled atmospheres like oxidizing or reducing). The tester visually observes the ash cone as it heats up and records the temperatures at which specific deformation stages occur:

- Initial Deformation Temperature (IDT): The temperature at which the first sign of rounding or bending of the sharp tip or edges of the cone occurs.

- Softening Temperature (ST): The temperature at which the cone tip bends over and touches the base, or when the cone deforms into a spherical shape.

- Hemispherical Temperature (HT): The temperature at which the ash cone forms a hemisphere (height becomes half the width at the base).

- Fluid Temperature (FT): The temperature at which the ash cone completely collapses into a flat liquid pool.

- Importance: These temperatures are critical for boiler design and operation, as they indicate the ash’s propensity to slag, foul, or clinker, which can lead to operational problems and efficiency loss.

CHN Analyzer

A CHN Analyzer is an elemental analysis instrument used to determine the carbon (C), hydrogen (H), and nitrogen (N) content in various organic and inorganic samples, including coal.

Importance: Provides essential data for the ultimate analysis of coal, which is critical for calculating its theoretical heat value, understanding its combustion stoichiometry, and assessing its environmental impact (e.g., NOx emissions).

Function: A small, precisely weighed coal sample is combusted at high temperatures in a pure oxygen atmosphere. The combustion products (CO₂, H₂O, and NₓOᵧ) are then passed through reduction columns and separated chromatographically. Detectors measure the amount of CO₂, H₂O, and N₂ produced, which are then converted into the percentages of C, H, and N in the original sample.

Typical Measurement: Results are expressed as weight percentages (wt%) of Carbon, Hydrogen, and Nitrogen.

Total Sulphur Analyzer

A Total Sulphur Analyzer is an instrument used to determine the total sulfur content in coal samples.

- Function: Various methods and instruments exist, but common principles involve:

- High-Temperature Combustion Method: A precisely weighed coal sample is combusted in a high-temperature furnace (e.g., 1350°C) in an oxygen atmosphere. Sulfur in the sample is converted into sulfur dioxide (SO₂). The SO₂ gas is then measured using techniques like infrared detection (most common) or titration.

- Typical Measurement: Results are expressed as weight percentage (wt%) of Total Sulfur.

- Importance: Sulfur content is a major quality parameter for coal due to its environmental implications (SOx emissions leading to acid rain) and its role in corrosion within power plants. It significantly impacts the market value and environmental regulations for coal usage.

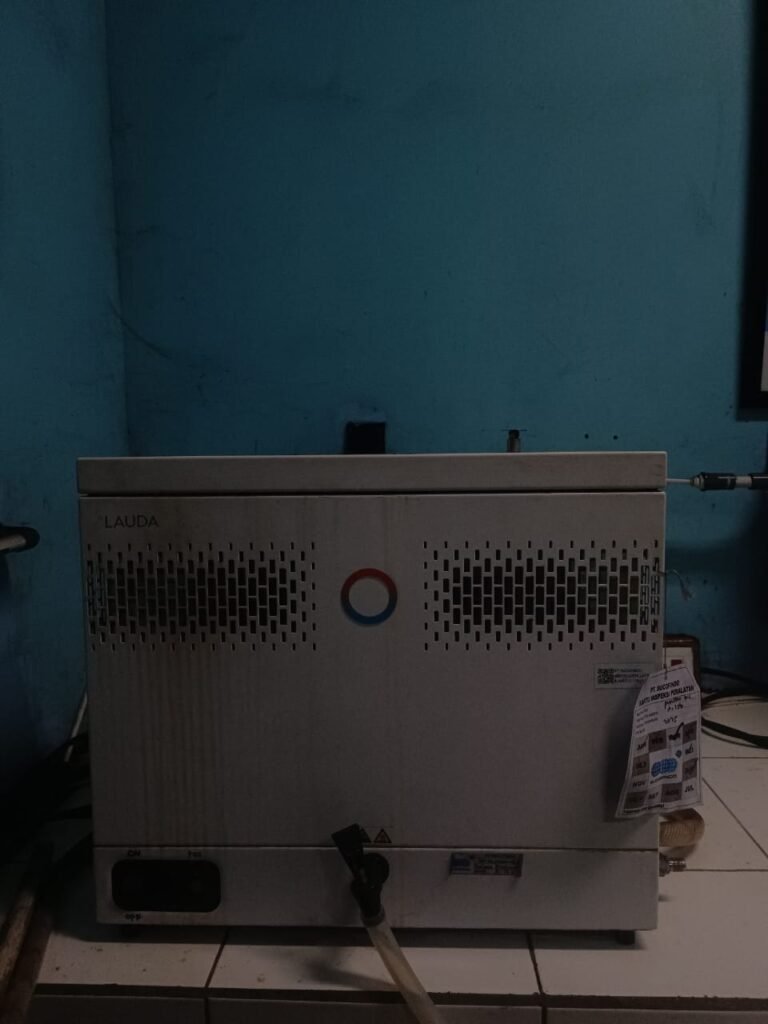

WATERBATH

A Water Bath is a common piece of laboratory equipment used to incubate samples at a constant temperature over a period of time. It provides a stable and uniform temperature environment, which is crucial for many sensitive analytical procedures.

- Function: It precisely heats samples placed in containers (like test tubes, flasks, or beakers) by immersing them in temperature-controlled water. This provides gentle and even heating, preventing localized overheating or direct exposure to flame, which can be damaging to certain samples or reagents.

- Typical Measurements/Features:

- Temperature Range: Typically operates from ambient temperature up to 100°C (the boiling point of water). Some specialized models might go slightly higher with specific bath fluids or offer cooling capabilities.

- Volume: Available in various sizes, from small benchtop units of a few liters (e.g., 2-5 liters) up to larger units of 20 liters or more.

- Temperature Control: Equipped with a digital or analog thermostat for precise temperature setting and regulation, often with an accuracy of ± 0.1°C to ± 0.5°C.

- Safety Features: Often includes features like over-temperature protection, low-liquid level cut-off, and covers to prevent evaporation and maintain temperature stability.

- Application in Coal Analysis:

- Sample Preparation: Used for heating coal digestates to dissolve certain elements before analysis by techniques like ICP or AAS.

- Digestion Procedures: Maintaining specific temperatures for chemical reactions during the dissolution of coal or ash samples.

- Total Moisture (Indirect Method): While the TM Direct method uses an oven, some less common methods or specific preparation steps might involve gentle heating in a water bath.

- Viscosity Measurements: For preparing samples or maintaining temperatures for viscosity tests of coal slurries or related liquids.

- Importance: Ensures consistent and reproducible heating conditions, which are vital for the accuracy and reliability of many chemical and physical tests in the coal laboratory.